- Home

- Products

- Steel Wire Rope

- Rotation Resistant Steel Wire Rope

Rotation Resistant Steel Wire Rope

Application

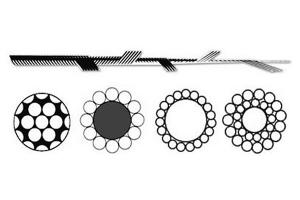

These anti-twist wire ropes are utilized for the production of large braid anti-twisting ropes. When braided together, the steel wires create an extremely strong cable that is also rotation resistant.

Characteristic

1. High tensile strength and outstanding wear resistance.

2. Straight and high quality casting.

3. Small tolerance and high flexibility

4. Produced according to QB/320281PF06-2006 standards as well as customized requirements.

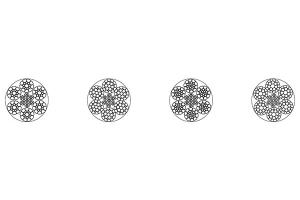

Product Structure

-

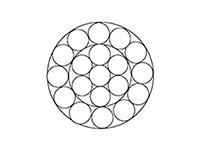

1×19

1×19 -

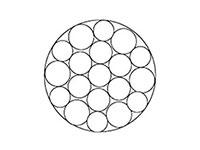

1×19W

1×19W -

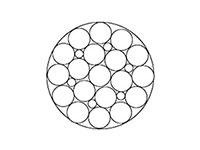

1×25Fi

1×25Fi -

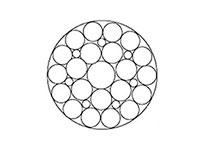

1×29Fi

1×29Fi

| 1×19 | ||||||

| Nominal Diameter |

Approximate Weight |

Nominal Tensile Strength, Mpa | ||||

| D | 1870 | 1960 | 2060 | 2160 | 2260 | |

| mm | kg/100m | Minimum Breaking Force (kN) | ||||

| 2.0 | 2.0 | 4.2 | 4.4 | 4.7 | 4.9 | 5.1 |

| 2.5 | 3.1 | 6.6 | 6.9 | 7.3 | 7.7 | 8.0 |

| 3.0 | 4.5 | 9.5 | 10.0 | 10.5 | 11.0 | 11.5 |

| 3.5 | 6.0 | 13.0 | 13.6 | 14.3 | 15.0 | 15.7 |

| 4.0 | 7.9 | 17.0 | 17.8 | 18.7 | 19.6 | 20.5 |

| 1×19W | ||||||

| Nominal Diameter |

Approximate Weight |

Nominal Tensile Strength, Mpa | ||||

| D | 1870 | 1960 | 2060 | 2160 | 2260 | |

| mm | kg/100m | Minimum Breaking Force (kN) | ||||

| 2.0 | 2.2 | 4.6 | 4.8 | 5.0 | 5.3 | 5.5 |

| 2.5 | 3.7 | 7.6 | 8.0 | 8.4 | 8.8 | 9.2 |

| 3.0 | 4.7 | 10.1 | 10.6 | 11.1 | 11.7 | 12.2 |

| 3.5 | 6.7 | 14.6 | 15.3 | 16.1 | 16.9 | 17.7 |

| 4.0 | 8.4 | 18.3 | 19.2 | 20.2 | 21.2 | 22.1 |

| 1×25Fi / 1×29Fi | ||||||

| Nominal Diameter |

Approximate Weight |

Nominal Tensile Strength, Mpa | ||||

| D | 1870 | 1960 | 2060 | 2160 | 2260 | |

| mm | kg/100m | Minimum Breaking Force (kN) | ||||

| 4.0 | 8.5 | 18.5 | 19.4 | 20.4 | 21.4 | 22.4 |

| 4.6 | 11.4 | 24.3 | 25.5 | 26.8 | 28.1 | 29.4 |

| 4.8 | 12.5 | 27.1 | 28.4 | 29.8 | 31.3 | 32.7 |

| 5.2 | 14.8 | 32.0 | 33.5 | 35.2 | 36.9 | 38.7 |

| 5.4 | 15.8 | 34.2 | 35.8 | 37.6 | 39.5 | 41.3 |

| 5.5 | 16.5 | 35.6 | 37.3 | 39.2 | 41.2 | 43.1 |

| 6.0 | 19.2 | 41.6 | 43.6 | 45.8 | 48.1 | 50.3 |

| 6.5 | 22.8 | 49.4 | 51.7 | 54.4 | 57.0 | 59.6 |

| 7.0 | 26.4 | 57.3 | 60.0 | 63.1 | 66.1 | 69.1 |

Inquiry Form